Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(0 votes)

(0 votes) Regulars

Offline

Offline

I see on ebay some $6 bridge-attachable piezo pickups for violins. Some of them include a bridge blank for that price.

They are around 6mm x 41mm, with a 9" lead and a 2.38 mm plug.

Anybody here applied one of those so as to electrify a fiddle? If so, could you give everybody some pointers?

A few questions spring to mind.

How do you attach the pickup to the bridge? Glue? What kind?

How do you physically set up the cables so that the bridge is not ripped out in case you accidentally pull on the lead?

What electronics are needed to drive: 1) headphones or ear buds, 2) practice amp/speaker, 3) 8-ohm speaker, 4) computer sound card, 5) digital recorder.

What sound quality should somebody expect from such a homemade rig?

FM sells a Super Sensitive pickup which needs mounting. It comes with a sticky clay. I put the pickup on the body but it would have fit on the bridge if I wanted.

The sound was good.

The attached picture also shows my cannabalized chin rest which has become a support strain relief.

It works but I now have a carpenter jack (1/4") and different pickup so the cable can be easily removed from the violin if desired.

Members

Offline

Offline

@RosinedUp: The rectangular piezos around 6mmX41mm usually go under the bridge feet, at least with electric voilins. They aren't glued, the pressure the strings push down on the bridge with are what holds them in place.

I haven't personally seen any pics or projects where people have put them on acoustic violins, but theoretically it should be possible. Might want to use a very thin piece of wood underneath it to keep it from marring the violin's top. Whether you do that or not, the thickness of the circuitboard piezos are usually mounted on will add a mm or so to the height of the bridge, but the bridge could be trimmed a little to compensate for that.

They also may work perfectly well glued to a face of the bridge, but i have never tried that.

If you could post a pic or two of what you have, it might make it easier to help you figure out what to do with it.

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

This is an excerpt from Bluestem Strings

Bridge Transducer

Bridge Transducer

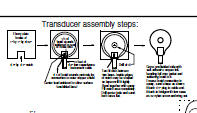

The transducer notes below cover the building of an extremely lightweight piezo-based bridge transducer that can convert ANY violin into an electric in seconds. I have tried many designs and I will say that this design sounds as good as any piezo-based transducer I've heard, on par with one of the commercially available sensor-in-bridge pickups that I have fitted to a few instruments. I lucked out in my experiments and came up with something that sounds good after a few failed initial attempts...a major accomplishment using this material. It uses a piezo disk salvaged from a musical greeting card (Yes, you can use the oft-cited Radio Shack piezo disk ripped from their little plastic case with two leads sticking out...)with a 10 foot length of special small diameter low capacitance output cable soldered to it, and then sandwiched between two thin shielded ebony faces. The circular transducer has a hole through the center and attaches in seconds to the bridge face with a low mass nylon screw and wing nut.

Bridge transducer features and construction notes:

- Transducer installs and removes in seconds

- Extremely low mass to minimize interaction with the sound produced by the string and instrument

- Inexpensive and easy to make

- Low capacitance output cable to minimize the edginess inherent in piezo-based transducers

- DO use a preamp if you want any high impedance transducer to sound good. (I'm happy with my $30 Behringer combo preamp/D.I.)

You will need:

(2) 1" by 1" by 3/32" ebony scraps from peg head veneer application (1) Piezo disk extracted from a musical greeting card Small amount of black 60 or 90 minute working time two-part epoxy 10 feet of George-L's 1/8" diameter instrument cable 1" by 1" piece of adhesive-backed copper foil for shielding the "hot" side of the transducer sandwich 1/4" solder connection male plug Assorted tools, 25 watt pencil soldering iron, small diameter rosin core solder, small rotary hobby tool fitted with a 3/4" sanding drum

1. Strip 1/2" of insulation from the cable; unravel the outer braid into two pieces on opposite sides of the cable end. Remove half of the strands from each side to eliminate bulkiness.

2. Cut a 1/4" square notch in the bottom edge of both 1" by 1" by 3/32" ebony squares to contain the solder joint.

3. Soldering the cable end to the disk comes next. Maneuver the wire ends to be perfectly positioned before soldering to the disk. You will want to position the cable so the "active" side of the disk will be perfectly flat when the transducer is completed. (That's important!) The piezo disk is easily damaged by excessive heat, so solder quickly using good technique. It's OK to practice this a few times, and you may ruin a disk getting the hang of working with these. Apply a small pad of solder to the disk where the wire will attach, tin the wire end, and solder the two together using as little heat and as little time as necessary. Solder one of the braided pieces to the rear brass surface of the piezo disk. The other braid will protrude for later attachment to the copper foil shielding surface. Solder the tip of the stripped center conductor to the silver surface on the other side of the disk

4. Fit the two ebony pieces to the disk with no gaps, with the notches over the solder joints. You may need to carve a little out on the inside edges of the notches to get them to fit perfectly. NOTE: Figure out a way to indicate which side the brass backing disk faces. This is the ground side, and the copper foil will be applied to the OPPOSITE or active side. This is important! Coat the mating surfaces with epoxy, place them together and weight or clamp the completed assembly over waxed paper until dry.

5. Drill the 3/16" hole through the center of the square and sand both sides flat. Draw out the circular shape on the finished assembly and sand to these lines, preferably with a small rotary hobby tool fitted with a 3/4" sanding drum. The edge of the brass disk will show...that's no problem.

6. Apply the self-adhesive copper foil to the "active" side of the assembly opposite the brass surface. (You remembered to mark the correct face, didn't you?) Bend the foil down over the small exposed braid area, solder the braid to it, trim, and coat this with epoxy to make an attractive joint.

7. Solder the plug on to the other end of the cable, making sure the center cable conductor is soldered to the center lug of the plug.

8. Mount the transducer with the copper foil covered "active" surface against the bridge face with a #8 by 32 by 3/4" long nylon screw and nylon wing nut and play away! My violin sounds much better with the transducer mounted towards the tailpiece, so you should experiment with placement on your instrument. You should have no hum, good signal strength, and a very pleasant tone, especially if you feed the transducer output to a pre-amp to match the high impedance of the piezo material to the input stage of your amp.

More information can be found at http://www.bluestemstrings.com.....geEV1.html

Regulars

Offline

Offline

Daniel: Here is a link to a photo

http://i00.i.aliimg.com/wsphot.....lesale.jpg

http://www.aliexpress.com/item.....07902.html

On ebay, search for "Piezo pickup for violin maker" or similar.

Because it has markings like "4G 3D 2A 1E" laid out corresponding to the physical layout of the strings, I thought it was supposed to be attached to the face of the bridge. But okay, you say it normally goes under the feet. I guess the pickup would have to be flexible in order to conform to the belly if used on an acoustic. Have you had one of these in your hand?

I didn't notice it before, but I guess that the descriptions do say that it is for an electric.

Members

Offline

Offline

Well, RosinedUp, just because that is the way it is usually done for electrics doesn't mean that it is the only way that it can work.

Piezo pickups work by a small piece of a particular kind of crystal being subjected to one of 3 kinds of stress. It is changes in pressure, vibration, or twist. The usual method for that shape is to put it under the bridge and rely on changes in pressure. But it could be mounted on a bridge face as you thought and work by vibration instead. Many of the piezo pickups used on acoustic violins that attach to the body work by vibration, so it obviously can work that way. It could probably also be mounted on the body, maybe someplace that doesn't show much, like under the tailpiece.

The stuff circuitboards are usually made of will bend a bit without breaking. That is what most of the rectangular pickups usually are, is circuitboard with just a tiny piece of the crystal on it. So long as the pickup itself is smooth enough to not scar up the finish on your violin, I'd say it will probably bend enough to fit the curve of the top of the violin when the pressure of the bridge and strings are on it.

So you do have plenty of options to try.

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

Unfortunately I am a lousey photographer but the piezo strip edge is easy to see running across the full width of the bridge.

I will add here an even worse picture that I took when the bridge fell over. You can see that it became two separate pieces. Dealer says "no problem" put is back together and sandwich the strip and all it well.

Members

Offline

Offline

That is seriously cool, Oliver. Never saw one made like that before. Brilliant notion, though. Is it glued together or sort of stacked without glue?

Now, back to the part of the question in the original post about the electronics. Are you looking to build it from scratch RosinedUp? Or more looking for what sort of circuitry to look for to buy?

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

It seems that the piezo strip element is somehow secured to the lower piece but I don't know if an adhesive was used or not.

However, my dealer did not mention any adhesive to re-build the bridge, only to stack it under the pressure of the strings.

I have to wonder, in this design, just how critical would be the location (height) of the bridge split junction ?

Incidentally, the e-violin here is an Aquila but I have seen the piezo strips for sale from other dealers. The strips can be nasty being micro-soldering might be required (?).

Regulars

Offline

Offline

Daniel, I need to know what kinds of components (pre-amp, amp, or whatever) I would need in order to output to the devices I enumerated in the OP. Then I can look at the costs and decide whether to buy or build.

I am not very averse to building some circuitry, only mildly so. My analog-electronics design skill is not great, though, so I would have to use someone else's design. I might be able to do some little adaptations to my situation if needed. If I can buy an amp or pre-amp off the shelf, I am inclined to do that unless I can save say $20 or more. If something like the amplifier circuit that ozmous posted on another thread is roughly as good as one I could buy, I would be happy enough to order parts from digikey and solder them together.

As for scrounging the pickup from a greeting card, I probably wouldn't, if I can use the rectangular pickup that I mentioned in the OP.

Regulars

Offline

Offline

Here are a couple off-the-shelf components that might be useful to me and others for electrifying an acoustic violin.

Search ebay for "Piezo Contact Pickup Violin" or similar. You will find a round stick-on pickup with 10" cable and 1/4" jack for about $5.5.

I found on ebay a violin bridge with a built-in piezo pickup for $12. Search for "Violin Pickup Bridge Built in Piezo" or similar. Not sure how others on ebay are selling what looks like about the same thing for 20 times as much.

Regulars

Offline

Offline

Thanks to all for the informative posts so far.

What do you all think of the following as a basic approach?

Parts:

* a bridge with a built-in piezo pickup ($12, pictured below)

* a female 1/4" mono audio connector ($1, also pictured below)

* a block of wood

* a chinrest clamp

Procedure:

* Unscrew the metal guts of the 1/4" connector from its plastic body and discard the plastic.

* Cut the little male plug off the lead of the bridge/pickup.

* Shape the block of wood so that it can be attached to the violin using the chinrest clamp. Drill the wood so that the guts of the 1/4" connector can be screwed into it.

* Solder the lead from the bridge/pickup to the connector.

I have these questions:

* Would it basically work?

* Would there be any issues with the soldering? I mean would it just be routine, or are the wires going to be too tiny, or are there any kind of noise-related issues such as impedance or whatever? I have soldered wires and cables many times, but am completely new to audio electronics.

* Would a 1/4" cable be the best? I think I would like a lighter cable if that is doable--if it doesn't have any disadvantages that would surprise me.

Members

Offline

Offline

Hmm.. Tell ya what, RosinedUp. I am going to intentional mis-hear what you said above and pretend that instead of saying that you'd buy it if it would save you 20$, that you want to spend about 20$ for the preamp.

http://www.ebay.com/itm/LC-4-P.....336f815505

Check that one. 4 band eq, with built in digital tuner. There's plenty of other ones as well, if you search under "piezo preamp" on ebay. That would get you up and running with an output similar to an electric guitar with no extra cutting, soldering or building. It is made to mount as a built-in on an acoustic guitar body, but a buck or two at the local craft store could get you a nice little wooden box to mount it on so it looks more finished (if you don't have some sort of box kicking around the house that you'd like for that).

Once you have that 1/4 inch jack at about electric guitar signal level, there;'s a ton of used gear you can use, since it will with about anything you can use with a guitar or a commercial electric or electrified violin. With a 4 band eq (or whatever you decide on), you can get the tone about where you like easy enough.

But maybe there is more. You are a Linux user? *IF* your "flavor" of Linux can work with JACK..

Check out guitarix and Rakarrack. Guitarix is an amplifier emulator and Rakarrack is an effects system with 17 effects to play with. All you'd need is a 1/4 inch to 1/8 inch cable to hook the preamp to your computer's soundcard, the same as any guitarist using those softwares would.

Now, there are some drawbacks to using a computer to emulate an effects rack and a guitar amp. Depending on how much speed and ram your computer has, you may get enough "latency" to add a little bit of a delay between when you play something and when it comes out of the speakers. The computer just takes a certain number of milliseconds to process the signal, and if the computer is slow enough and you are running enough stages of signal processing or effects, it can be noticeable and/or a bit annoying, at least at first.

But it would be a pretty sweet setup to try different effects and amp characteristics to figure out what you might want to look for in used gear.. I'd say the price is right. LOL

(Added on the edit) Oh, and i almost forgot. I think your mounting plan and etc sound very sensible. They are very similar to the ways some of the nice high-end commercial systems attach.

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

Regulars

Offline

Offline

Thank you, Daniel. I think I am starting to get the bigger picture now.

ooh yeah: integrated preamp, equalizer, and tuner. That should be good for intonation training, for one thing. That ebay listing is a little confused though, as it has pictures of both a 4-band EQ and a 5-band EQ. I found this other listing of a 5-band EQ for $14.70. http://www.ebay.com/itm/110927.....23.l2649

The preamp comes with a guitar pickup, and I see that the short cable from the guitar pickup to the preamp has a metal sheath. So I wonder about the cable that would go from the connector on the fiddle to the preamp, which is conceptually an extension of the cable from the pickup. First, I think I would like to change the design to use a lighter cable, as I mentioned in my previous post. So I guess I would switch to a 1/8" connector and use a light cable, say 10 to 15 feet long. I would cut the little plug from the guitar pickup and solder it onto the end of the long cable and plug it into the preamp. Does that sound like it would work okay?

Still I am worried about noise and signal-transmission issues, as I don't know anything about that. So I think I need some help with that. Kevin's post (thanks, Kevin) above mentions "a 10 foot length of special small diameter low capacitance output cable" and "10 feet of George-L's 1/8" diameter instrument cable". Is this a kind of coaxial cable? I see some George L products for sale, but it looks like the George L connectors come in non-standard sizes (0.155" and 0.225"). Yet I don't see them selling jacks to match, so I am confused. I would favor standard, compatible materials. Also they seem a little pricey (near $2 per foot of cable). Can I get some understanding about selecting or designing a cable?

1 Guest(s)

Log In

Log In Register

Register