Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(0 votes)

(0 votes) Regulars

Offline

Offline

It's a beautiful violin, the back seems to be bird eye maple. I can't see any cracks from your pictures but you could check by shining lights into f holes in the dark. It seems like you will need a chin rest, and the violin needs to be clean up a little. The other thing is, your grandpa had changed the pegs into a mechanic one like those for guitar. When he put those in, he might have to drill the peg holes bigger so i don't know if you could put regular pegs back on (this remind me of CatMcCalls new project with enlarged peg holes, same thing might have been done to her violin). the bow probably needs to be rehaired and you will need new strings.

You have a great violin to start with, enjoy playing!

Regulars

Offline

Offline

Yes, it's a good looking instrument.

I've heard mechanical pegs make changing the strings a bit more difficult but I don't really know. All I know is that they'd be perfect on a steampunk-inspired violin. (No, I don't have plans to make a steampunk violin in the future when I have a job and money. Why do you ask? ![]() )

)

Regulars

Offline

Offline

Grandma says that Grandpa was adamant about getting the mechanical pegs. I am guessing bumping around on country dirt roads in a model A had a lot to do with it. He played dances all over the countryside, and never let any grass grow under his wheels! I am guessing it took less tuning with the metal pegs?

I am waiting for my daughters cheap 1/2 size violin to arrive so I can borrow her rosin. Hopefully this weekend we can get started on our fiddlin' fun together!![]()

Regulars

Offline

Offline

Regulars

Offline

Offline

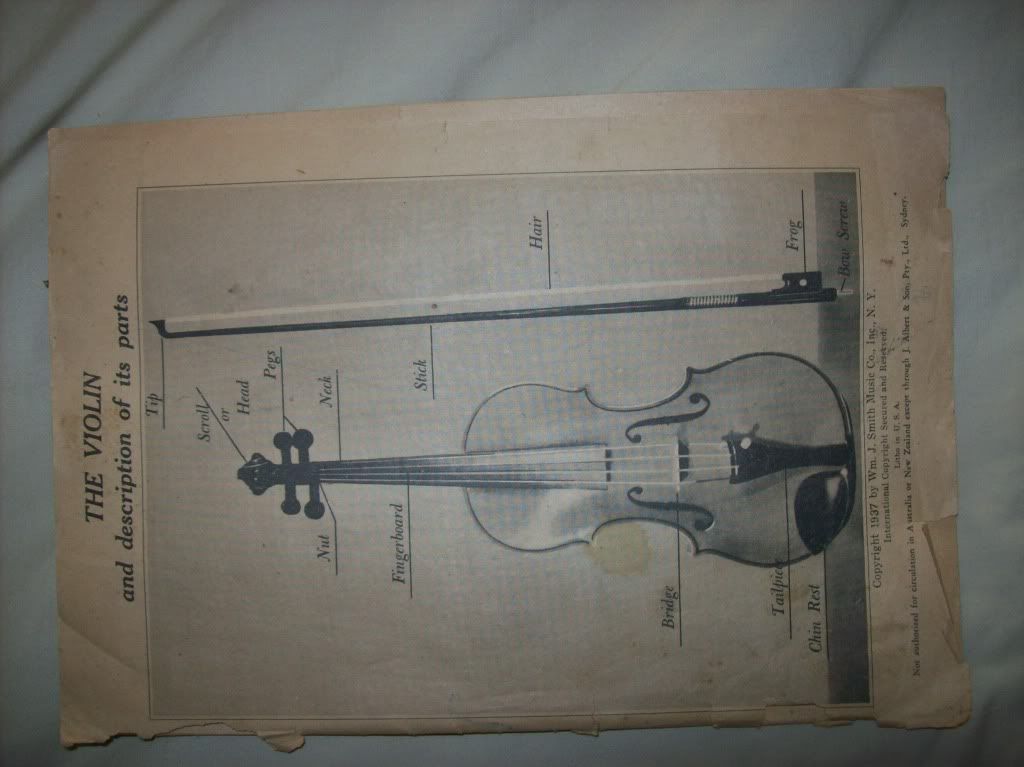

The last picture is the old learn-to-play booklet that was in the case, dated 1936 I think. The pegs are stuck, and you can see where one of the grips totally crumbled away on the right side when I tried to turn it. ![]()

Sooooo, my new project is doing something about it. THEN hopefully my next project will be learning to play!

Regulars

Regulars

Offline

Offline

Terry said

Hmm yeah, it almost looks like there is a screw in the end of the cog. They might be a kind of tensioner or locking mechanism.

Can you get WD40 in the US. It's a lubricant/releasing spray

Oh, yes. WD40 is second only to duct tape in home repair usefulness. As the old saying goes, "If it's moving and it shouldn't be, use duct tape. If it isn't moving and it should be, use WD40." ![]()

Honorary advisor

Regulars

Yeah - don't use WD40 anywhere near that fiddle! It's a very bad idea. Really. Use sewing machine oil, or better still, Tri-Flow. Both will wipe off easier and not damage the varnish.

WD40 is actually a bad idea for many of the applications we tend to use it for as it leaves residue that can do a lot of damage to things like sewing machines. Srsly.

Violin machine heads are available online and it would be a pretty simple operation to replace them. If the tuning pegs are crumbling, chances are the whole thing has seized up and will continue to deteriorate.

Mary in Springfield, Oregon http://www.thefiddleandbanjopr.....dpress.com

Regulars

Offline

Offline

Honorary advisor

Regulars

dionysia said

Totally off topic, but my Grandma swears daily applications of WD-40 eased her arthritis in her knee, staving off the need for surgery until she was about 85 or so.

I tend to think it was the massaging action, but who am I to contradict Grandma?

Yikes! Not likely, but who can refute Folk Cures? ![]() Can't stand the stuff myself, the smell makes my head ache.

Can't stand the stuff myself, the smell makes my head ache.

Mary in Springfield, Oregon http://www.thefiddleandbanjopr.....dpress.com

http://dmiemail.stewmac.com/t/.....88969/718/

http://dmiemail.stewmac.com/t/.....88845/667/

| When plastic tuner knobs get really old, they eventually rot away. This happened to some tuners my friend Spencer Bohren sent me. One set was from his old Supro lap steel (I worked on that guitar in Trade Secrets #150). The other set dated all the way back to 1897, on Spencer’s Bruno parlor guitar. (Those 19th-Century knobs were probably made of celluloid.) |

|

|||||

|

|

|||||

|

The easy way: Our vintage 3-on-a-plate tuners are a direct replacement. They’re an exact fit, and they work better than the originals did when new. |

Vintage-style 3-on-Plate Tuners Vintage-style 3-on-Plate Tuners |

||||

|

Bite off the old: Fret cutters snip away the knobs, neat and clean. When you get close to the shaft, “nibble” until the last of the plastic comes free. Clean up the exposed shafts with a wire brush, then degrease them with naphtha. |

Fret Cutter Fret Cutter |

||||

|

||||||

|

Just like the old Kluson knobs, our vintage replacement knobs have a rectangular hole. The tuner shaft is heated and pressed into this hole, melting its way in. |

Vintage-style Tuner Knobs Vintage-style Tuner Knobs |

||||

|

Drilling a hole exactly in the center of a rectangle is hard to do without this tip: a “centering stick” for positioning the knob exactly right below my drill press chuck. |

Nut and Saddle Vise Nut and Saddle Vise |

||||

|

The hole is right on dead center. This knob will fit the shaft perfectly. |

|||||

|

Heat from a soldering gun. I heat the shaft with a Weller soldering iron. I've modified the gun’s tip by cutting its copper loop. The gun won’t heat unless this tip’s circuit is intact; when the two cut ends touch the shaft, the circuit is completed and the metal gets hot quickly. You can also use a regular soldering iron for heat, as long as it’s at least 30 watts. |

StewMac Super Glue StewMac Super Glue |

||||

|

A little insurance. Once the knobs are on, I run water-thin #10 super glue down the shaft to fill any gaps and make the joint even stronger. I use a pipette, but for better reach and a lighter flow of glue, I cut the pipette’s tip off and replace it with a whip tip. |

Pipettes Pipettes |

||||

|

It’s surprising how sometimes a set of old Klusons will be shiny and clean even though the knobs are so rotten. With the new knobs, these old tuners (on the left) look almost like the new ones on the right. I’ve sent the re-knobbed old tuners back to my friend Spencer, and he’s happy! | |||||

Regulars

Offline

Offline

Thanks for the post Kevin.

I took the advice offered by Cat and others and used some sewing machine oil on my tuners. They are now unfrozen ![]() but the strings won't tune up. I have two pegs that need new knobs, and I am going to buy new strings. THEN I hope to be off and running with the learning to play.

but the strings won't tune up. I have two pegs that need new knobs, and I am going to buy new strings. THEN I hope to be off and running with the learning to play.![]()

I can get the G string to hit the note and stay there for a few minutes. The other strings are pretty much hopeless, as they won't hit the note and stay there long enough to put a bow to it.

Sooo, off to the Fiddlershop I go!![]()

1 Guest(s)

Log In

Log In Register

Register