Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(0 votes)

(0 votes) Regulars

Offline

Offline

I have a second batch of violin bridges and a cello bridge in the oven. 2 hr at 390 F upper rack position convection fan on--no effect. Raised temperature to 395 F (I know that 400 F works). I also put in 2 each ebony violin bridges since I had them.

I am now questioning the figure of 380F for maple I heard in a video. He was an end user and not someone that did the toasting. I did an internet search and could not find specific temperature numbers for any given wood species. I think that this is a "trade secret" area. I did find that researchers in europe "deep fried" wood to toast it (not specified in article, but I bet they used non flammable heat exchange fluid) to avoid using nitrogen.

I don't have any spruce available but I have a lot of cedar so I was going to cut some of that up tomorrow to see at what temperature that toasts at. They are both softwoods so the temperature should be similar.

I have read that toasted wood is more difficult to glue than regular wood. I will use the cedar to look into that.

I also read on the internet that attempting to roast wood without all the water removed will cause a mottled condition which is unattractive. Water (and steam) is excellent at heat absorption so that is understandable.

I am bidding on some violins with broken necks so I should have some front and back material to work on soon.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Hmm... are you sure of the temperature though? What I noticed with convection ovens during regular cooking for example is that the temperature varies greatly between brands even as much as 20 degrees.. I have one that's consistently about 20 degrees colder than another if I set both to 200 C. Maybe if you have a multimeter with a temperature sensor you can somehow stick that in and compare, till you figure out the oven you bought.

Regulars

Offline

Offline

Hi Ferenc Simon. I could not agree more with you about the oven temperature. I believe that it is keeping a consistent temperature but I have no clue as to "Natural Bureau of Standards" accurate temperature. After all, I only paid $40 for it new through a Amazon Warehouse deal LOL. I have several multi meters but lack the temperature sensor. I do have a digital "meat probe" that I could calibrate at 32 F and 212 F, create a graph and compare it with "displayed" temperature of the toaster oven. Same technology.

I am finding out that the "toasting" is very temperature sensitive in that no effect is observed at 2 hr at 395 F (displayed) and a very significant change occurs at 400 F (displayed). Things that I have found out thus far.

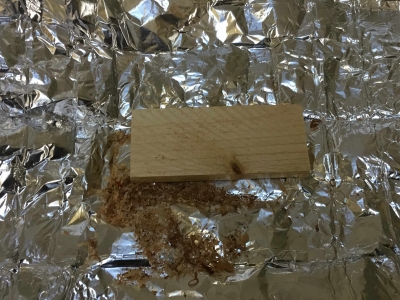

1. A small amount of pre treated (2 hr at 200 F "displayed" to remove moisture) saw dust appears to be an effective oxygen "getter" when use in combination with an aluminum foil enclosure. I am using 1/2 teaspoon per violin bridge.

2. 400 F (displayed) appears to be the magic temperature for maple.

3. You have to watch out for ebony inserts or you will lose them. I am trying a batch now that were not shaped to see if I can put a drop of super glue on them after the roasting to hold in the ebony.

4. The roasted bridges definitely have a "ring" to them when dropped. I have not autoclaved them yet so this might not be a final property.

I plan to send some of the bridges to Fiddlerman so that he can have his luthiers look at them.

I am definitely having some fun with my $40 investment with the toaster oven.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Hi Ferenc Simon (and others). You were right, the digital reading of my toaster oven was way off! It was reading 400 F and my meat thermometer said that the oven was 348 F. I then found a laboratory mercury thermometer that went to 400 F, so I put that in and it read 346 F (it's a good thing that I don't live in California, or that mercury thermometer would give me cancer).

I don't know what type of paint they use for the manufacturer's logo on a maple violin bridge, but roasting has no effect on it (perhaps they burn them on). All of the ebony inserts were intact on this batch, but I will superglue them to be sure.

The roasting effect on the cello bridge is not as pretty as on the violin bridges, so I am going to try a different packaging arrangement before I attempt to roast another one.

I am going to keep raising the oven temperature until I see some effect on ebony. No joy as of yet.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I just found out that the building code in Massachusetts (the next state over from me) requires spruce studs, joists, and rafters. So I now found an inexpensive supply of spruce material for my roasting experiments.

I ran my first samples through an autoclave and they still "click" when dropped.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I just took out the 2 maple violin fingerboards and saw tears in the aluminum foil wrapping and faint areas of oxidation in the maple immediately around the tear. I think that it will sand out, but I will use a more robust method of sealing larger items in the future. I have thicker aluminum foil.

I saw in a Youtube video that luthiers were not able to bend wood after it had been roasted. I will try to see if wood that has previously been bent will retain its shape when subjected to roasting.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

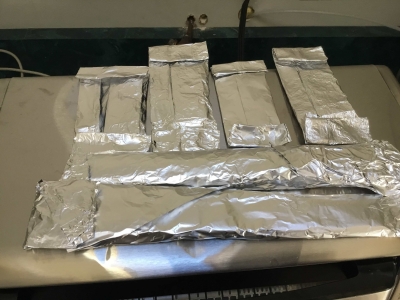

By doing multiple roastings I have determined that what is taking place is a one time chemical reaction in the wood and you cannot look at it in terms of cooking. If, for example, you extend the time of the roast or have it occur at a higher temperature than needed, no additional effect occurs (the wood does not get any darker). This is important because I am introducing a shrink wrap vinyl film as an intermediate between two aluminum foil layers to prevent item loss in the event of a tear in the aluminum foil (losing a Chinese violin bridge to oxygen is of little importance, but losing a maple fingerboard begins to hurt the pocketbook).

The first photo is of a spruce wood sample after roasting, showing how the saw dust is almost consumed by oxidation. The second is of wrapped items.

_

_

_

_

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I just purchased a 3/4 sized old german violin for $20 that I thought would be perfect for my experiments (1 piece front and back) but it is so nice that I hesitate to destroy it.

I have been trying to find a temperature where a "Freeze Rite" vinyl cooking wrap melted but retained a sealing layer between two sheets of aluminum foil. It looks like 360 F (actual temperature) is the magic number. I believe that this is the secret to roasting larger items without aluminum foil failure.

I graphed the roasting oven temperature error and will edit my previous posts to provide actual (mercury thermometer) readings. I think that this is important since the internet appears to be providing wildly misleading information and making this process appear more difficult than it is.

My next step is to see if roasting makes it harder to glue the wood.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

In looking at ways to keep unused Tru-Oil from filming over, I found several products that are argon gas in a can. Art 18 and Preserve (marketed to keep opened wine fresh in the bottle) and Bloxygen (marketed to keep wood finish fresh in the bottle) are some that I found. I think that they could also be used to roast wood, but on a small scale the use of aluminum foil and saw dust works fine.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I just received feedback from Alex of the Fiddlershop on the roasted violin bridges I sent them. The lutheriers wanted the wood to be "more crisp." This is certainly due to putting them in an autoclave after roasting, since they were clicking like poker chips before the autoclave step. I am roasting another batch of bridges and will send them without the autoclave step.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I got a "life time" supply of violin and cello sound posts coming from China. I will be roasting some of these shortly.

I just roasted a maple violin tailpiece for 6 hours and it came out very well. Perhaps the best ever. I am thinking of using ground fallen leaves as a "getter." They should have even more surface area than saw dust.

I am thinking of constructing a practice violin with roasted spruce and maple parts, finished in Tru Oil. That should be different.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I am back at it again. Roasted 6 each violin and cello sound posts. I am going to send half of them to the Fiddler Shop for their evaluation. The violin sound posts came out really dark, almost ebony in color. I am thinking that there must have been a lot of sugar in the wood.

I also roasted a maple violin fingerboard and neck. The neck presented an interesting problem in that I had to fill the peg box with something to eliminate the air void. I came up with using pop corn kernals. I dried them at 200 F for six hours, then used them with a little saw dust to fill up the peg box void. Worked well.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Hi all. I was looking at the Stew Mac web site and discovered that they are now selling Torrefied uncarved guitar braces out of Sitka Spruce (Item #4657) for $10.17 each. Since you need 7 or 8 of these pieces for a guitar, that is quite an expense.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Notes to file.

I made some sample roasted bridges last night for a local luthier using his (much more expensive than mine) stock. A cello bridge and a violin bridge. I noticed that I could fill the void between the feet of the cello bridge by inserting three violin bridges sideways. I nested his violin bridge between two of my Chinese examples. I had very good results.

The cello bridge had no oxidation splotches and the centered violin bridge has a jewel like light refraction property that I have not seen in previous attempts. The interior surfaces of the two Chinese bridges exhibited similar jewel like effects.

I have always wrapped each violin bridge separately for even heat distribution and short roasting interval. This may have been a mistake. Filling the void of a cello bridge worked great, and is now my standard procedure. And I am now going to stack multiple violin bridges to enhance their appearance.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

I still have a steamed bent section of a cello rib that I have done nothing with because I could not come up with a good method of sealing it with aluminum foil. New proposed method for roasting. I am going to use a disposable aluminum pan covered with aluminum foil and exclude oxygen by the use of argon from a spray can. I will also put in some bridges to see what happens.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Offline

Offline

For your roasting of violin parts have you considered buying cheap kits on Ebay? They're like 40 bucks unfinished with everything. If you watch the auctions you might be able to nick a few No reserve options for cheaper.

this technique reminds me a lot of color case hardening on gun parts. You heat up the parts in a metal box with different mixtures of ash and bone dust which burn differently in the lack of oxygen. The results are those finishes you commonly see on cowboy guns.

Wait I'm an ex welder! I might be able to add insight into this. you might be able to find a small GMAW welding canister on craigslist or so. If you go to any welding supply place you can get it refilled for dirt cheap if its a standard size I'm talking like 30 dollars the last time I got one filled with pure argon.

If you wanted too you might be able to make a metal box Fill it up with argon. Argon is heavier than air and in a confined space it doesn't take much argon to displace any oxygen.

Regulars

Offline

Offline

@Batto and others. I already have access to argon at home. I am trying to keep the procedure simple and tech free so that more people will try it. I don’t think that I am succeeding in that regard.

Violin plates are beyond the capacity of my toaster oven and the hide glue will not withstand the roasting temperature.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Offline

Offline

Irv said

@Batto and others. I already have access to argon at home. I am trying to keep the procedure simple and tech free so that more people will try it. I don’t think that I am succeeding in that regard.Violin plates are beyond the capacity of my toaster oven and the hide glue will not withstand the roasting temperature.

For small parts like bridges it seems feasible, but yeah hide glue won't last but it would be interesting to see what each part ends up as. Still while most people wouldn't know how to source argon.

a 1 piece back would be interesting to see the result of.

I do wonder if an electric smoker would be suitable for this. I've normalized case hardening after quenching in one of those by leaving it at 400 degrees for a few hours, and the size of those units are quite large. You can find them fairly affordable.

Also reduces the risk of in house problems. Like somebody wanting to a cook a pizza or the other half not amused at your exploits with the oven.

I'm curious as well.

Regulars

Offline

Offline

I have already tried it on spruce and made a take down practice violin out of it. Roasted spruce glued up very well. Certainly possible to use a kitchen oven, but I generally avoid doing that. I also made an oven for roasting split bamboo violin bows using a hot air gun and a section of b vent. I lined the interior of the vent with ceramic fiber paper to get a faster response.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

1 Guest(s)

Log In

Log In Register

Register