Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(1 votes)

(1 votes) Regulars

Offline

Offline

@@steveduf. I have not purchased through them, but they were recommended to me. Try Rio Grande Jewelry Supply 0.999 fine silver wire (6 through 32 gauge).

A bow that I really like uses 0.2 mm silver wire and it looks like they pull ends of wire under wrap with a string. Generally, the ends are soldered.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Honorary advisor

Regulars

Offline

OfflineRegulars

Online

Online

Hmmm...

If I had to predict the future (possibly in a way that only a violinist with @Fiddlerman's experience could comment), what about altering weight distribution and reducing frog weight? I get the impression that the frog may only be necessary for the current weight distribution. What if it could be reduced to zero and the carbon's weight distribution profile be engineered instead? This would require a completely different hair-tightening mechanism, e.g. a small hinge and a carbon lever to open it out, thus creating pull.

How would you like a bow that weighed 30g, 20g? I'd understand if you'd hate it. I suppose you have to balance hand-applied pressure and the effortless pressure from the bow's weight. No bow weight might, counter-intuitively, cause too much RH fatigue.

Or maybe double-bass rosin would solve that problem?  (lol)

(lol)

Andrew

Verified human - the ignominy!

Honorary advisor

Regulars

Offline

OfflineGordon Shumway said

Hmmm...If I had to predict the future (possibly in a way that only a violinist with @Fiddlerman's experience could comment), what about altering weight distribution and reducing frog weight? I get the impression that the frog may only be necessary for the current weight distribution. What if it could be reduced to zero and the carbon's weight distribution profile be engineered instead? This would require a completely different hair-tightening mechanism, e.g. a small hinge and a carbon lever to open it out, thus creating pull.

How would you like a bow that weighed 30g, 20g? I'd understand if you'd hate it. I suppose you have to balance hand-applied pressure and the effortless pressure from the bow's weight. No bow weight might, counter-intuitively, cause too much RH fatigue.

Or maybe double-bass rosin would solve that problem?

(lol)

When I changed from a wooden bow to Fiddlerman's Carbon fiber bow, the weight was the same but the balance was shifted 4 inches towards the frog. I changed to a dark rosin and added pressure to compensate. I wouldn't want anything that felt lighter than what I am working with now.

For a bow hair adjuster, each time you tighten the frog, you tighten to a different extent. You compensate for humidity and personal preference. I live close to a major river in the US and somedays my bow hair is tight before i turn the screw and others it flops around on the stick. I think this effect caused a wooden bow to warp. I really liked that bow.

Regulars

Offline

Offline

Well, I have filled a 2 inch binder with information so far on this stuff.

I like the research that Vuillaume did on the Francois Xavier Tourte (1750-1835) bows and plan to base my tapers on their work. Why this is not commonly done in the trade is beyond me. Particularly in the cf bows that are made in a mold.

Corker made use of technology involved in making bamboo fly rods. I only wrinkle that I will add is to wrap the bamboo strips while in the conventional heat treating process for double bonding (roasting). The Corker technique could also be used with a variety of wood species.

A metal or cf bow head will eliminate inherent wood grain weakness.

The major problem with the frog is in the mortise wear caused by long term use.

The Heddon steel bow was originally quite light. I recently purchased a later example of a more normal weight, so I don’t think there was much of a market for light weight bows. These are very interesting bows that do not cost much to try.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Irv, I got curious about your choice of bamboo (à la Corker) so I looked up the properties of bamboo compared to brazilwood. Yeah, I realize there are many types and qualities of each.

In case anyone else is curious:

https://www.wood-database.com/.....razilwood/

https://www.wood-database.com/bamboo/

If I read the info correctly, generic brazilwood is about twice as dense and twice as hard as bamboo (but similarly elastic.) Is part of your idea of roasting the bamboo to get it to approach the hardness and density qualities of brazilwood?

As for me, the only thing I roast in chicken (not you, "Chicken")

Regulars

Offline

Offline

Modulus

The key comparison is the elastic modulus numbers. They are very similar. Bamboo is stronger per unit weight. Unshown in your chart is that bamboo is further strengthened by heat treatment (by about 1/3). I think that this will be enhanced to an unknown degree by oxygen exclusion during heat treatment (which will substitute double bonds in the lignin).

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Honorary advisor

Regulars

Offline

Offline@bocaholly Thanks for the laugh, I needed that. A-musing is all I'm good for these days. I just had a piece of steel pulled out of my eye and I wasn't even working on anything. Just walking down a sidewalk and it fell out of the sky. Seriously, stuck me just above the pupil. Doctor said, "Wow, You are lucky!" If I was so lucky it would have hit the guy that left it there and not me. Further convinced I am cursed.

Just a sliver of metal but big enough to really mess up my plans for a bit. Guess I need to start wearing a helmet and pads when I leave the house.

In past dealings with bamboo, it is often used to imitate the density of bone, for those that practice cutting bone with a sword. It is still used as a major building implement in much of china. I think a bamboo bow would last a person a lifetime and has been under utilized in western culture. The speed at which bamboo can grow is phenomenal. I used to have a small field of bamboo in my little swamp of a back yard and sold it off as fishing poles. Built chicken coops out of it, duck blinds, deer blinds, I love it.

When Irv gets this all figured out, I will be one of first customers. Guaranteed.

Regulars

Offline

Offline

Holy moly, Chicken! Sounds like your eye is going to be OK but that is one scary happening (and you've said you've been through many!) Are you wearing a patch on your eye for a while or just bandaged up above it?

Bamboo... yes, very cool stuff. Looks nice ... then multiplies and looks beautiful... until it proliferates to the point where all there is is bamboo growing outside your back window (tried that as you might guess 🙂 Love your idea of building stuff with it... be it chicken coops or Irv's bows. So many pics of amazing bamboo architecture online... this one must have been made out of ginormous shoots:

Honorary advisor

Regulars

Offline

Offlinebandaged up at the moment. Supposed to be on til tomorrow and change the dressing. Affected my sinuses and I can't see anything out of either eye. Bright lights horrible. Feel drunk but I don't do painkillers. Have numbing eyedrop with an antibiotic.

Thank you.

Bamboo will continue to grow thicker and thicker. Glad to be out of the swamp tho. mosquito magnet.

Regulars

Offline

Offline

Honorary advisor

Regulars

Offline

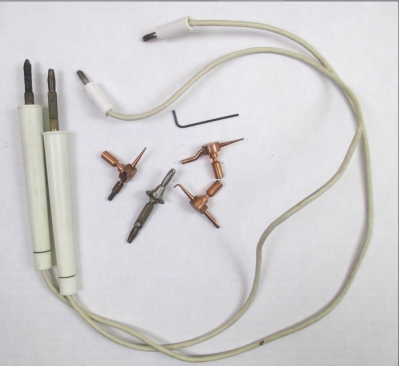

OfflineUsed to use carbon rods to weld carbon steel. CAW carbon arc welding. the carbon rod is graphite.

Capacitive Discharge Resistance Welding is basically a spot weld. Your releasing a large amount of energy in a short period of time. The advantage is you don't heat up large amounts of metal, just the small area that the charge is delivered which gives a more stable weld for certain metals. If you weld thin angle iron with fcaw or mig or whatever, you heat larger areas of the metal and the rise and fall in temperature in the surrounding area can cause the metal to become weak. so if the metal is continuously flexed it will break close to the weld from because of the heat transfer. this won't happen with cdr because there is no heat expansion.

cdr can be used on everything depending on the size of the machine. aluminum, stainless, carbon based materials.

Will it weld tungsten with a graphite rod? Carbon welding usually hits a temperature of 5400 degrees and tungsten sits at 6200, BUT, your not welding saw blades and a lot of melt temperature depends on thickness and dispersion of heat. so a carbon rod could weld tungsten in cdw if the thickness is low. And the heat is concentrated in that one spot for just a millisecond.

I think that it needs to be noted that 1. cdw was replaced years ago with tcdw or twin arc. 2 TIG can be accomplished on a small scale.

If you have a setup with carbon rods, definitely give it try. Carbon steel is no joke in hardness. those chrome bumpers that beat up telephone poles, carbon steel. Much thicker than wire.

1 Guest(s)

Log In

Log In Register

Register