Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(2 votes)

(2 votes) Regulars

Opportunity is often missed because it wears suspenders and looks like hard work.

Members

Offline

Offline

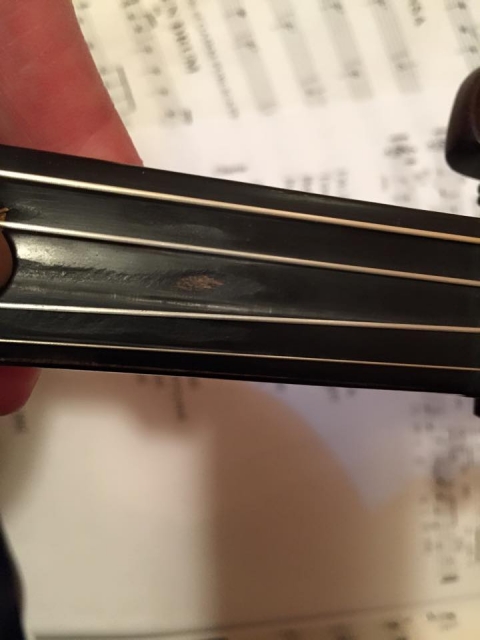

I suppose it could be from normal wear if you play a LOT.. But it doesn't seem likely since it looks like it has gone right through the ebony? And I would think if it was wear it would be in more than one spot.

Hard to say from a picture, but I would almost wonder if there was a problem with the wood there on the fingerboard like a deep gouge or ding and it got "fixed" with some sort of dark wood filling compound.

There is a "fix" that could be done on a rut like that, if you aren't going to be able to afford to get a luthier to put on a new fingerboard or tackle doing a fingerboard replacement yourself. But I'll wait to let the more experienced folks chime in before talking about it, lest the rotten tomatoes start getting flung. LOL

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

Regulars

I do play it a lot lol. Eh I play every day, almost without fail, with the exception of a few days in Feb. when I am off working a remote location and am too busy to barely breath. There is another spot I was just trying to get one of them in really good focus. We don't have any luthiers here. I think I'll just keep playing it until I can get another one, then I'll try my hand at fixing or replacing.

Opportunity is often missed because it wears suspenders and looks like hard work.

Members

Offline

Offline

Ok, I'll explain what I would do, short of buying a new fingerboard and cracking off the old one and gluing on a new one and then having to trim and plane it down and worrying about getting the 'scoop" and radius right and etc..

I have fixed similar ruts in guitar fretboards (I've never tried it on a violin, but logically it should work the same) with "super glue". Cyanoacrylate. You use the thin stuff, not the "gel" kind. The gel tends to chip out easier, I don't know why.

First you clean the area with naphthalene. That's lighter fluid, like "Zippo". That will remove the finger oils, any traces of any polish, etc to get a clean surface for the glue. If the fingerboard is dyed, it may also wipe off some of the dye, so it might be a good idea to check on an inconspicuous part of the fingerboard first to see if you're going to be wiping off some of the black. Wet the damaged area down and wipe it out with a paper towel several times, to get it as clean is you reasonably can.

Once it is cleaned out, let it dry overnight to make sure there are no traces of the naphthalene.

Then you put in a few drops of super glue and spread them around with a toothpick. Thin layer. Don't try to fill it in just one or two coats. Expect it to take several. Let each layer dry about half an hour, and use a clean toothpick to touch a shiny part of it to see if it is actually still wet. Don't use your finger to check it because you can feel very silly rummaging around for the nail polish remover to get loose from the glue with a musical instrument stuck to your hand. As layers dry, keep adding a new layer until it is built up to just a teeny bit above the existing fingerboard.

Let it dry for at least a couple hours and then scrape or sand the "patch" down to feel level with the rest of the fingerboard.

That's it. It does work, and the "patch" will usually hold up better than the original ebony did, since cyanoacrylate is harder than ebony. It is also a very inexpensive repair. That's the good points.

The main bad point is that it is clear and that can look a bit peculiar. But no worse than it looks now, and playability should be just about exactly like it was when new.

So that's the basic trick/fix. There are a couple of upgrades (mostly cosmetic) that you can do as well.

The first is if you can find a piece of scrap ebony or other dark wood to sand and get a bit of fine sawdust from. If you sprinkle a little of that with each layer, you can get a better colour match. The problem, of course, is that most people don't have scrap ebony or similarly dark hardwood just lying around.

The second is a bit more work. You can take something like a razor blade or X-acto knife and make shallow cuts along the grain of the wood in the damaged area. you only want to go maybe a mm deep and make them parallel and close together, maybe half a mm apart of less. Then after that bit of "shredding", go through with tweezers or something similar and lift the thin strips of wood you made, to break them loose from the main wood of the fingerboard just enough to get them to the top or a tiny bit above where your patch will come to. Then when you fill in your layers of cyanoacrylate, it sets around the wood fibers you separated out and you preserve the look of the woodgrain more.

If you do a good job of that, it is possible to fix a rut so that even on a very close inspection it would be hard to tell there ever was a rut there. That's the good part. The bad part is that it is a lot more work and time and I don't think it is any stronger than the simple patch I explained at the beginning. Also doing a good job of it will take some luck to manage on your first try.

Some people may mention that you can add a little baking soda to the superglue to speed up the drying time. While that is true, I don't do that trick in a fix like this. If you add just a little too much, then you may not have enough working time before the stuff sets. The baking soda also may not fully dissolve before the glue sets, giving you translucent white areas and you may get some air bubbles in it. It's a good trick for some things, but not for filling a rut on a dark coloured piece of wood, in my opinion.

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

Regulars

Thanks. That sounds like something I can do pretty easily.

Opportunity is often missed because it wears suspenders and looks like hard work.

Honorary tenured advisor

Regulars

Offline

OfflineSome of those grooves are pretty deep and it looks like it may have worn all the way through the ebony, exposing the wood of the neck underneath in one spot. I would say that a fingerboard replacement would be in order. There are a couple of places in Anchorage that you might call, if you don't want to ship it down to the lower 48. If it's cheap enough, it might be worth considering a professional replacement.

A positive attitude may not solve all your problems, but it will annoy enough people to make it worth the effort. ~Herm Albright

Members

Offline

Offline

They make black superglue????

Ok I looked on Amazon and yeah they do.. It is toughened with rubber fibers to even make it less brittle.

Why am I always the last to hear of these things?

Yeah, I've only ever used the plain clear. But the "toughened" black would probably be an even better choice. It wouldn't "chip out" like the clear sometimes (actually pretty rare, but still sometimes) does.

Good find, Pierre.

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

Regulars

Lol I giggled at the JB Weld. Ok, well not doing anything with it until after I get back from my work on the checkpoint and then Fiddlefest.

Opportunity is often missed because it wears suspenders and looks like hard work.

Members

Offline

Offline

While I haven't ever done the technique I described on a violin fingerboard, I did do it a few months ago on the fretboard for one of my acoustic guitars. I thought an idea of what such a "fix" actually can end up looking like might be good to show.

It took a few tried to get an angle where the flash reflection actually makes it possible to see the fixed spots. To a casual inspection, even looking pretty close, it is not likely to be noticed. In normal playing situations, I'd bet a dozen donuts that it wouldn't be noticed. To the fingers, it feels like the fretboard was never damaged.

Now, the ruts I was fixing weren't *quite* as deep as what you showed in the pic, but some were at least close. At the third fret under the treble strings the ruts were at least 3 mm deep. This is the fretboard of a 40 yr old guitar, it had some wear to it when I got it about 20 yrs ago and I've played the crap out of it since then. LOL

That fingerboard is rosewood, which is a little softer than ebony. It had ruts worn in it under almost all the strings, and all the way up to the 7th fret. I didn't have a matching colour of fine sawdust, so I used the "shredding" sort of method I explained for the deep ones, and the simpler method of just using CA (cyanoacrylate or "super glue") for the ones that weren't as bad. But every fret position up to the 7th fret needed at least some repair to the fretboard. Some of them were at least close to what you are looking at on your violin fingerboard.

I can't say about the black CA glue or JB Weld. Never used those for this, but at least you can see what plain old cheap (got mine at the dollar store for 2 tubes for a buck, it took 3 tubes to do this particular fretboard) CA/superglue can do with primitive tools as explained and just working on a kitchen table.

I feel it looks decent, it has worked well, and it has worked well on other guitars I have done it with over the years. It is something you can do yourself, and if you don't like how it turns out, then learning to replace the fingerboard yourself or taking it to a luthier would still be there as options. As long as you don't go way into the wood of the neck under the fingerboard, I doubt that a luthier (or you) would have any serious additional problems with getting the old fingerboard off.

"This young wine may have a lot of tannins now, but in 5 or 10 years it is going to be spectacular, despite the fact that right now it tastes like crude oil. You know this is how it is supposed to taste at this stage of development." ~ Itzhak Perlman

1 Guest(s)

Log In

Log In Register

Register