Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(0 votes)

(0 votes)  Offline

Offline

Hello!

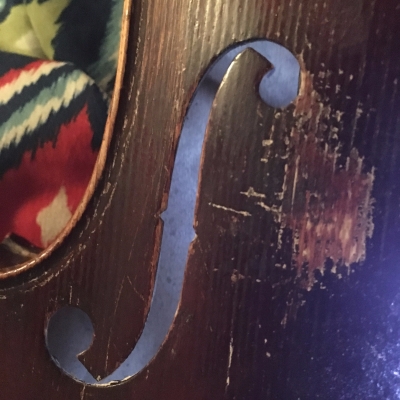

As you can gather from the title I have a very old violin and recently the bottom seam is opening up. I have included a bunch of pictures trying to capture, the problem as well show the violin itself. I know to most this may not be a desirable violin (especially considering the back isn't flamed) but despite these cosmetic issues it has a wonderful sound and is very old and does not appear to be a German trade fiddle (it has corner blocks, a non integral sound bar, the purfling is decent with sharp beestings and even the back even though its not flamed is bookmarked symmetrically.) In fact I'm not even sure the back is maple, I don't even know how old it is?

But what I can do to fix this? I can't exactly take it to a luthier as there are none around me for I live in the middle of nowhere, and frankly this seam is opening up at an alarming rate.

I am quite technically minded, and I am very good at repairing stuff. So what would be the proper procedure to take on this sort of thing. I know I would need to use hide glue, but I've worked with that in my life. (not even certain on the "proper" ways of heating it up!)

I just want to repair my violin so I can practice without the fear of the back popping off.

Regulars

Offline

Offline

Hello @Batto and others. Welcome to the forum.

Your violin is a clever fellow and chose to dispense with a seam instead of cracking. The seam is much easier to repair.

First, I recommend that you make some luthier clamps out of cork, wood, threaded rod and wing nuts (see photos). An alternative is a set of small grip clamps that go for about $2 each at Wal Mart or Harbor Freight. If you elect to use hide glue, it needs to be warmed in a double boiler. I use a fondue sized slow cooker that I got on eBay for $10. You can also use the original Titebond and get the purists in an uproar.

Clean the joint surfaces with an exacto knife or similar, apply glue with artist brush, and clamp. You need to work quickly with hide glue. Titebond is easier to work with. Remove excess glue with a damp tissue. Loads of videos on YouTube for guidance. Once glued, tap around both plates with fingers and listen for looseness to make sure you have not missed an area.

Once complete, post a picture and you may be awarded with a diy badge. And look at my thread to make a diy case humidifier so that you can avoid repeating your efforts. Good luck.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

If it was me, not knowing the age, origin, or materials of the violin, I would send this off to @Fiddlerman and have his people take a look.

But then, I am not that ambitious about repairing these instruments.

Plus, for all you know this could be a very valuable instrument, which generally require the work of an expert.

- Pete -

Offline

Offline

thank for you the follow up.

I am definitely going to be looking into that. I do wonder just how much of the seam is exposed as I suspect the 'patented mar 3 1883' chinrest is the only reason why the other side didn't explode.

I don't want to use titebound as I actually really care about this instrument. So much so that looking at ones on the fiddler man shop felt like cheating and watching your dog die. Why even the Carbon fiber violin I was comparing it to, and even my friend upon listening to the reviews of the violins for offer was "there's no point in getting another one."

So the hide glue double boiler thing. So how is this done? A mason jar I've seen referenced, but I'm not 100% sure.. really this is the only part of the equation I haven't fully figured out yet.

And I also got a German trade fiddle that's in pieces, and I got a bunch of tools coming to help assemble that, including sound post tools, as well as templates for the fingerboard , and two bridge templates which show detail for everything.

If I begin to work on that one I'll definitely start a thread and show my progress. But right now I'm mourning the loss of my violin as I really wish I could practice...

Regulars

Offline

Offline

I strongly suggest you view the YouTube video series on constructing a violin by Jon Mangum. He has a step by step process that uses a minimum of expensive machinery.

Hide glue is typically sold in flakes that are dissolved in water in a covered glass container (I use baby food jars). Over time it gets contaminated with bacteria and begins to smell. You do not want to mix up a quart of this stuff. You heat the jar in a water bath before use.

Hide glue was high tech 300 years ago. It bonds to itself (rare among glues) and it is easy to take things apart by reheating the glue (excellent if you have to replace a fingerboard, not so great if you leave the violin in the car during the summer). And as you found out, if you are lucky, the glue often fails before the shrinking of the plates causes a crack.

I am not convinced that the “masters” would continue with the use of hide glue given modern alternatives such as Titebond. But it is, of course, your violin and choice.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

@Batto . You mentioned instructions and templates for making a bridge. Are the templates for putting a radius on top of an existing bridge or are they for making the actual bridge from a block of quarter sawn maple? I have posted several unusual bridge designs (see mutant bridge thread) and would like to make my own bridges. Any information you have on this would be greatly welcomed.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Offline

Offline

@Pete_Violin my biggest thing is cost. Sending it off to who ever is always the first suggestion and it usually seems to end up with a price tag of 400-600 or being told your violin is firewood. Also it more often than not seems like these old violins aren’t worth the money you put in them unless they’re a confirmed bench made violin.

@Irv these are templates for shaping pre-existing blanks as well as the fingerboard radius.

I of course loosen the strings and took pictures, I popped off the tail piece and looked inside. I will gladly post the pictures of the instrument to get opinions on the quality of my violin.

Offline

Offline

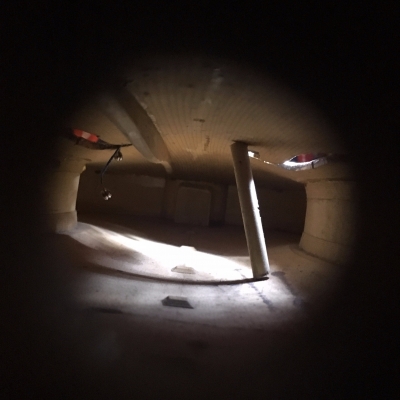

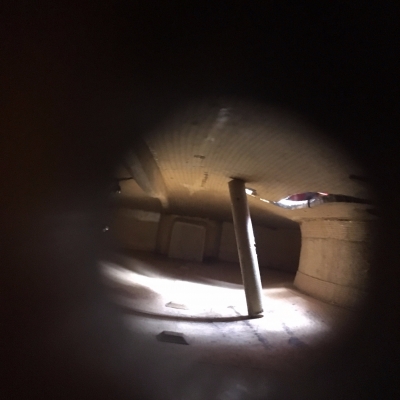

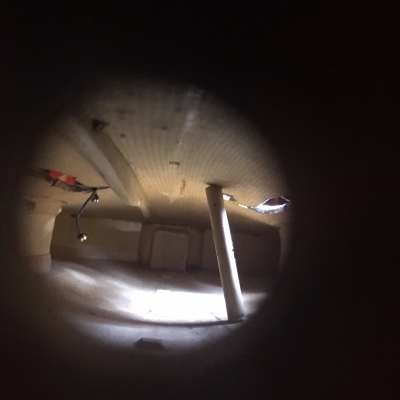

I am including pictures of what I have seen so far and yeah the sound post is really wonky... I'm surprised the violin sounded so nicely with a wonky soundpost... either that or it recently shifted... I don't know.

I was able to get some decent pictures of the inside of the violin. It does have corner blocks and the top looks to be carved nicely, the bass bar isn't carved out of the top.The only odd thing is that extra block towards the neck.

and of course the sound post fell, but such is life!

Regulars

Offline

Offline

@Batto . A couple of observations while looking at the photos.

The violin’s previous owner was adventurous. The string adjusters appear to be very well made. I have not seen that type of chin rest attachment mechanism before. The bridge is very well cut (the parchment goes under the e string). The fingerboard frets is a decal and can be removed as your playing improves, if you wish. The cleats running down the center line of the back plate may be original to the making of the violin. I am struck by how clean the interior of the corpus is (shaking a few table spoons of rice in the body is a common method of removing dust and dirt).

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Regulars

Offline

Offline

Irv said

I am struck by how clean the interior of the corpus is

That was my second thought.

My first thought was, where on earth did that bridge spend most of its time sitting?

I used to prime artist's canvases with rabbitskin glue, and I never used a doubleboiler. Afaik, the glue just had to be hot and not boiling, so I warmed it up gently on the stove in an old pot and then took it off again.

Andrew

Verified human - the ignominy!

Offline

Offline

Irv said

@Batto . A couple of observations while looking at the photos.The violin’s previous owner was adventurous. The string adjusters appear to be very well made. I have not seen that type of chin rest attachment mechanism before. The bridge is very well cut (the parchment goes under the e string). The fingerboard frets is a decal and can be removed as your playing improves, if you wish. The cleats running down the center line of the back plate may be original to the making of the violin. I am struck by how clean the interior of the corpus is (shaking a few table spoons of rice in the body is a common method of removing dust and dirt).

The string adjusters are a very old style(They have photos from the 1870's with that style of mechanical tuners) that is usually disregarded because its not pegs and people complain about the weight. However this violin even with those is very light. I placed on the fretboard sticker in order to help me get a basis but the fingerboard is ebony, and I was impressed by the quality of the inside as well.

The bridge is cut in a fiddle style and I am not certain if the date is 2008 or 1908!

The chin rest is a style I've only seen two of, and it is very study yet slim style which I myself enjoy as it is the most comfortable.

In fact if I got another violin I'd have a hell of time hunting down another example of such a chin rest. The tail piece is ebony and has Germany stamped on it. However tail pieces can be replaced.

The violin looks to be well made, and I got it for cheap on Ebay because of the tuners and the cosmetic condition.

But the condition isn't from neglect it was from getting the ever living snot played out of it.

It was one of those gut feelings, and I do enjoy this violin. There's something about I can't put my fingers on. So wether I repair it or send it out, I just want it to be in good hands...

and frankly I'd rather not have the bridge or nut replaced however.. I have noticed its a bit hard to hit the A string without a risk of hitting the D or the E. So it is a much flatter cut. However considering I lean more towards the enjoyment of the fiddle music I see this as a plus, more than a con.

The violin also had a rich darker sound, almost what I would associate commonly with Gypsy playing, and other forms of playing.

The age of violin is still something I have no way to identify as there is no label, or a sign of a label ever being present in the violin itself, and the simple fact that everything is aged properly, and the use of old parts which show their age and even tell a story says a lot about the instrument.

If this thing could speak I wonder what tales it could tell?

Offline

Offline

Gordon Shumway said

Irv said

I am struck by how clean the interior of the corpus isThat was my second thought.

My first thought was, where on earth did that bridge spend most of its time sitting?

I used to prime artist's canvases with rabbitskin glue, and I never used a doubleboiler. Afaik, the glue just had to be hot and not boiling, so I warmed it up gently on the stove in an old pot and then took it off again.

I'm guessing 'bridges' because from what it looks like the damage occurred from falling bridges and what I suspect may have been from strings breaking. Probably while playing.

I don't know I haven't seen many violins with that style of damage to be honest, but I don't feel its from neglect per se, and as I've mentioned in the prior posts this violin's bridge was cut with a flatter fiddle cut.

Regulars

Offline

Offline

Irv said

@Gordon Stumway. My only nod to tradition is to heat hide glue in a water bath, and you are telling me it is a waste of time. Have you no shame, man?I see another experiment taking shape.

It may depend on how long you will be working with the glue - long periods and the double-boiler will be very convenient. In fact, I may have misremembered - I may have put a roasting dish full of water on a gas stove and put the pot in that.

But afaicr, the real thing to avoid is letting the glue boil.

Modern glues are almost powdered so you just need to pour hot water on them really. A quick once around the edge of a fiddle doesn't seem like enough work to warrant a double-boiler. But if you have glue in sheet form, a double-boiler will make cooking it up safer.

Andrew

Verified human - the ignominy!

Regulars

Offline

Offline

Batto said

the back even though its not flamed is bookmarked symmetrically

When you say the back isn't flamed, do you mean not obviously flamed? I wonder if I'm looking at flaming that is hidden by too much varnish? It looks like the back is in two halves and done quite nicely. Is that what bookmarked means?

Isn't that peghead really heavy?

I don't think it's the sort of fiddle I'd want to pay 500 for on EBay, but if I found it in a junk shop, I might be happy that I'd discovered a gem.

Is it my imagination, or is that neck really narrow?

Andrew

Verified human - the ignominy!

Regulars

Offline

Offline

@Batto . Your second photo shows a crack on the rib by the chin rest. I would be interested in a photo of the interior of this area.

Extensively played violins generally have fingerboard gouging near the nut. Did you notice any before you applied the fret decal? If not, it is likely a newer fingerboard (or the previous owner religiously washed hands before use).

Making a new bridge with a more pronounced top radius is not difficult. I would completely mimic the heart carvings of the original. That guy (or gal) knew what he/she was doing.

Kidding aside, putting water in a fondue sized crock pot is a simple means of temperate heating of hide glue. Getting a good bond is important.

Fancy grain pattern has no bearing on instrument performance. You obviously have a player and like the sound. Enjoy it.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Offline

Offline

Gordon Shumway said

Batto said

the back even though its not flamed is bookmarked symmetricallyWhen you say the back isn't flamed, do you mean not obviously flamed? I wonder if I'm looking at flaming that is hidden by too much varnish? It looks like the back is in two halves and done quite nicely. Is that what bookmarked means?

Isn't that peghead really heavy?

I don't think it's the sort of fiddle I'd want to pay 500 for on EBay, but if I found it in a junk shop, I might be happy that I'd discovered a gem.

Is it my imagination, or is that neck really narrow?

The back doesn't have that ornate heavily visible flames that are the cats meow and a symbol of ultimate status... despite the fact I have cheap fiddle I sold to a friend that's flamed and beautiful, yet is cheap... very cheap.

what I mean by bookmarked is the process of making a two piece back. You take the slab of wood cut it in half and then fold It out. You should get a symmetrical piece. Some violins are not made from the same wood, like the cheap violin I mentioned earlier. So you don't get that mirror affect. This violin while not having heavy flaming does show a good mirroring.

If what I am saying is making sense (I've done a bit of research on the processes of making a violin...in fact one of my dreams awhile back was to become a luthier)

I didn't pay 500 for it, I paid 148 with a coffin case shipped. The only thing I did to it was install fiddlerman strings.(and the decal)

I've never had any problems with the peg head... in fact the peg head makes fine tuners irrelevant. Just like the planetary pegs, only from the 1800's

I feel no issues with the weight and I am able to do this without any effort... or was the violin is currently in its coffin case in a state that saddens me.

However this shall not be a closed casket.

I can not really vouch for the narrowness of the neck.. well I can take measurements between 4 different fiddles I have and compare it if wanted.

Regulars

Offline

Offline

Batto said

bookmarked is the process of making a two piece back. You take the slab of wood cut it in half and then fold It out. You should get a symmetrical piece.

Yes, that's what they do with the walnut veneer in Rolls Royces to make the dashboard symmetrical, lol! On a fiddle, I'm not sure why you'd go to that trouble with something that isn't nicely flamed maple.

Andrew

Verified human - the ignominy!

1 Guest(s)

Log In

Log In Register

Register