Welcome to our forum. A Message To Our New and Prospective Members . Check out our Forum Rules. Lets keep this forum an enjoyable place to visit.

Currently working on errors from the latest (SimplePress) forum update. Many issues have been resoled and others are being worked on. Thank you for your patience.

Topic RSS

Topic RSS

(0 votes)

(0 votes)  Offline

Offline

vaguely on topic. I purchased 100 wooden truck wheels to use with carriage bolts in order to make violin top clamps. Its worth the slightly extra cost to not have me be cutting and drilling holes.

Also truth be told I'm not sure how much physical activity I can endure. Truth be told the reason why I'm so down about my violin is the fact I went through a terrible car accident that has left me with a concussion (amongst other issues). So learning how to play my violin (or attempting to again) was kinda a healthy use of my time.

Offline

Offline

Fiddlerman said

Batto said

vaguely on topic. I purchased 100 wooden truck wheels to use with carriage bolts in order to make violin top clamps. Its worth the slightly extra cost to not have me be cutting and drilling holes......Sounds like a great idea. How much did they cost you?

Sorry to hear about the accident.

22 dollars for 100 of them from Ebay. A bit on the overkill side yes, but the ability to make fifty clamps for a fraction of the price you see them made online is a positive.

Also I like making my own stuff, and lets face it taking a wooden dowel and cutting 100 sections of it of in 1/2 inch thick sections is time consuming.

When they get here I'll post pictures of the clamps. Its really simple and frankly with using the wheels you don't even need to be truly technically minded.

Offline

Offline

I decided to be ballsy and jumped right in. The results were pleasent

.

.

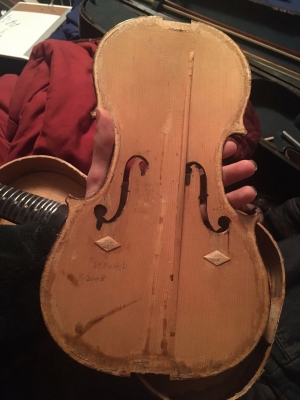

But yes. It has full corner blocks and everything looks nice. But there were a few surprises.

Theres a crack here its tiny, but its where it goes under the neck. I'm not sure how to fix this

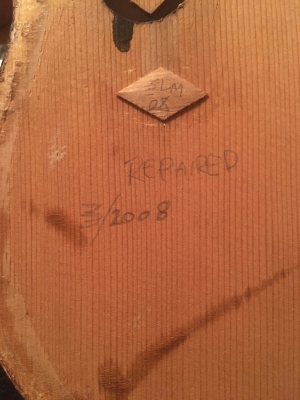

3/2008 funny it took 11 years for it fail exactly.

The two pointed earlier out cracks were repaired, but the top is gorgeously made.

here @Irv the inside you wanted to see closer up.

I'm really relieved to see how nice the inside of this violin looks, and the fact the corner blocks look original to it. I have no idea what country this violin came from or where it was made.

Anybody have any idea now that it's open?

:edit: theres also a small crack leading up the bass bar. it stops directly before the bassbar. I took a flashlight to the top and yeah it stops directly before the bassbar so the bass bar actually stopped this fine crack from expanding. I'm suspecting this came from the fact that the seams opened open and the chin rest was squeezing the area looks fixable.

Regulars

Offline

Offline

I believe that the area of the rib repair is represented in the last photo. It looks like glue was dabbled by the use of a long brush from the f hole. While the plate is off, it may be useful to remove excess glue from this area and glue a few maple cleats across crack. Make sure that grain is 90 degrees to direction of rib grain.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Offline

Offline

steveduf said

And the addiction begins...

Irv said

I believe that the area of the rib repair is represented in the last photo. It looks like glue was dabbled by the use of a long brush from the f hole. While the plate is off, it may be useful to remove excess glue from this area and glue a few maple cleats across crack. Make sure that grain is 90 degrees to direction of rib grain.

It was always present, but now I have the motivation and the tools to do so.

Makes sense as I have evidence to believe the rib was cracked by somebody fighting the chin rest too much and crushing the rib. So a quick (OH CRAP OH CRAP OH CRAP) moment with hide glue and a long bush seems possible... if it is even hide glue.

Still I'm really pleased with what I see. I was afraid I'd see false corner blocks but seeing properly fitted ones that look original to the violin is a positive sign as well as the smoothness of everything, that combined with the symmetrically book marked back tells me that somebody took their time making this violin.

Now I just need to wait for the rest of my tools to arrive. One of them arrived but that won't be used for this violin. It's a Stanley 102 planer, it's what a lot of violin makers recommend to use when planing fingerboards so that will be more helpful with the German trade fiddle.

Regulars

Offline

Offline

I can see Fiddlerman anxiously awaiting a violin sell after viewing those photos.

Seriously, you might want to scrape the old glue off the mating surfaces to save some weight and to provide a more secure surface for new glue.

Success is the progressive realisation of a worthy ideal. —Earl Nightingale.

Offline

Offline

Irv said

I can see Fiddlerman anxiously awaiting a violin sell after viewing those photos.Seriously, you might want to scrape the old glue off the mating surfaces to save some weight and to provide a more secure surface for new glue.

thats the plan. Well except for losing this violin. Thats not an option..

and besides the fiddler man is making a sale via the high quality sound posts he sells and the rosin. I need to see though when my tools are arriving.

Regulars

Offline

Offline

Batto said

these ones look used, where did you find these? I have found a part of a project so destiny is calling for a project.

I apologize, I just realized this, these are mine

you can have them for 20 bucks delivered in the US. Here is the damage to the violin they were installed on

i will not ever install them on one of mine

Regulars

Online

Online

1 Guest(s)

Log In

Log In Register

Register